Chocolarder Chocolate

Chocolarder Chocolate

Award Winning

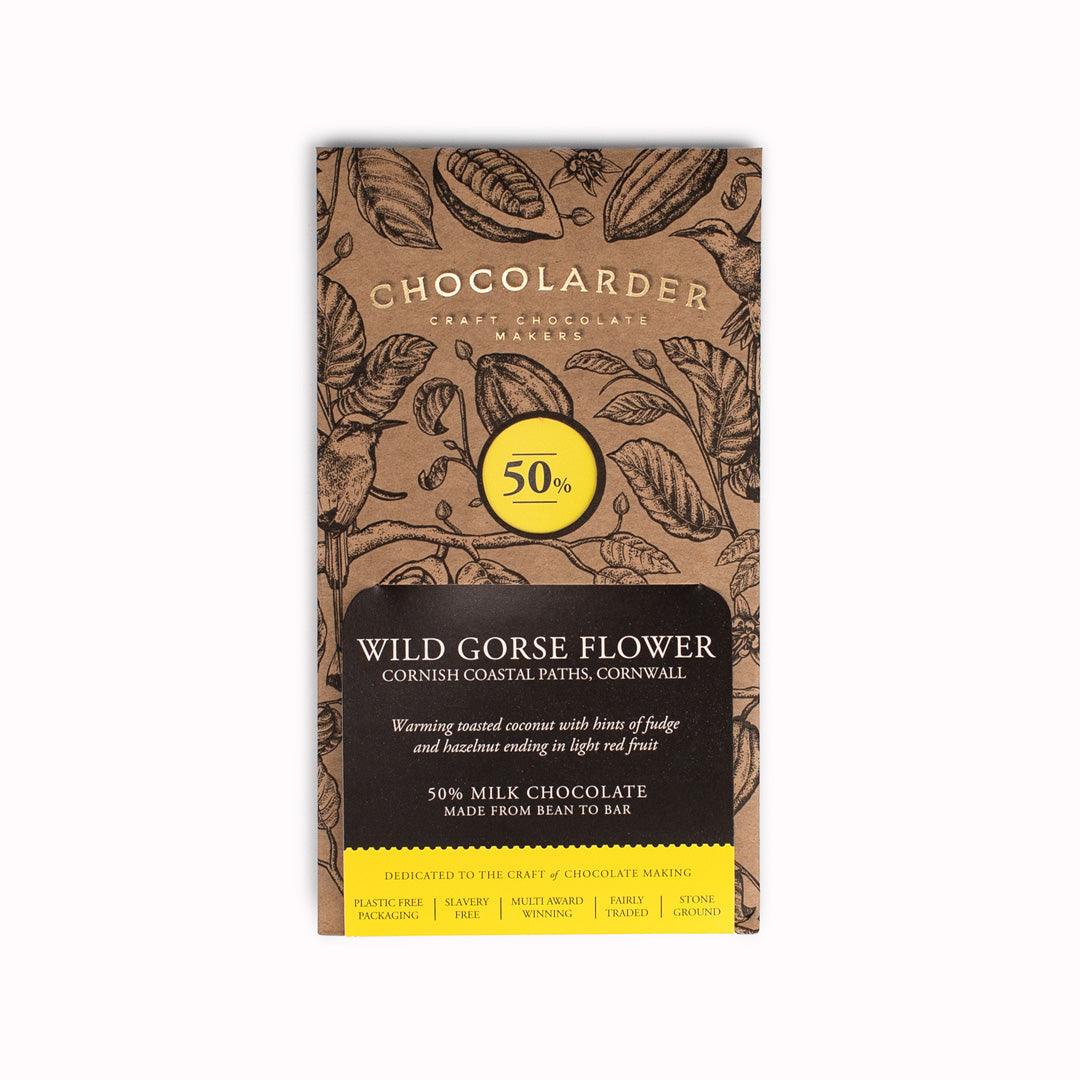

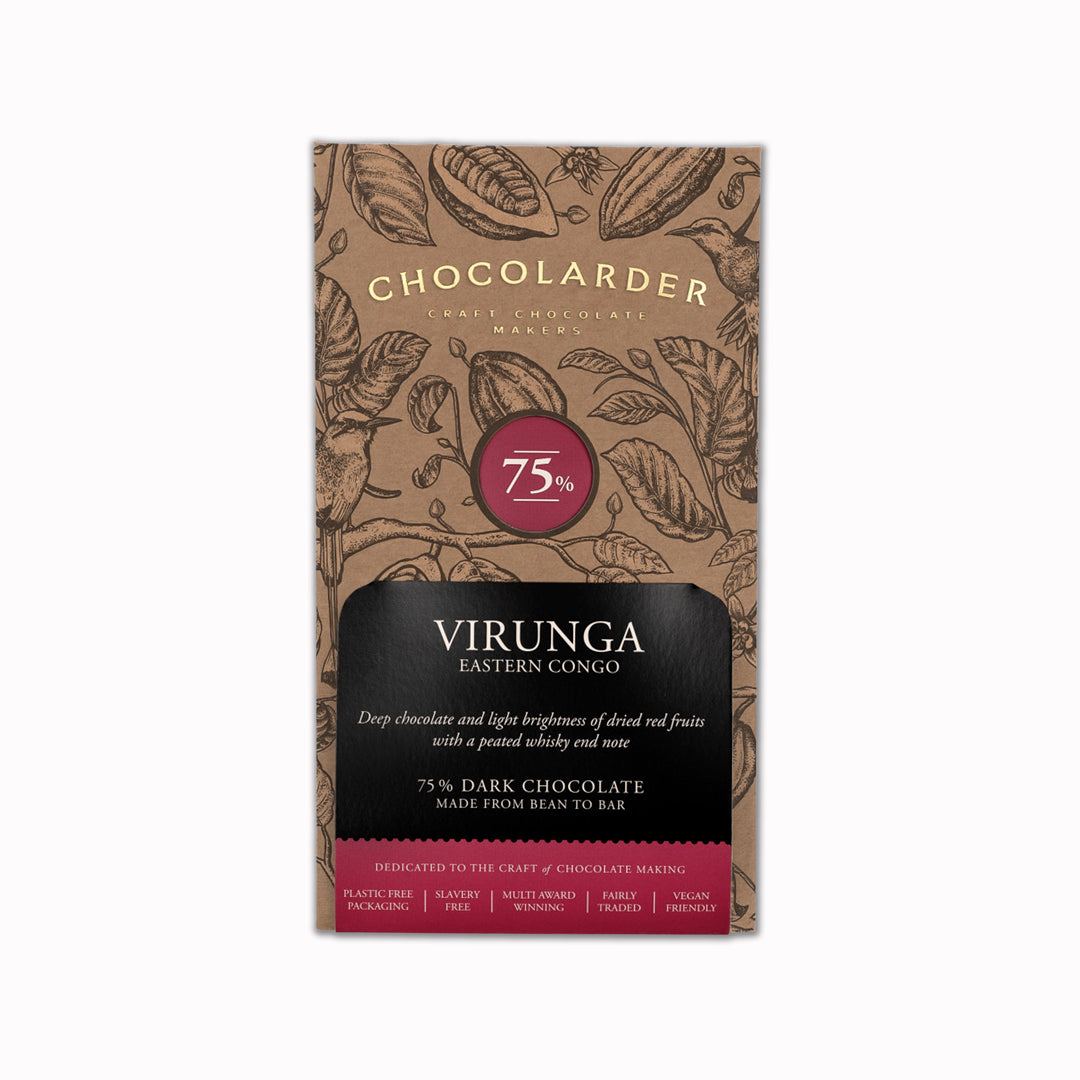

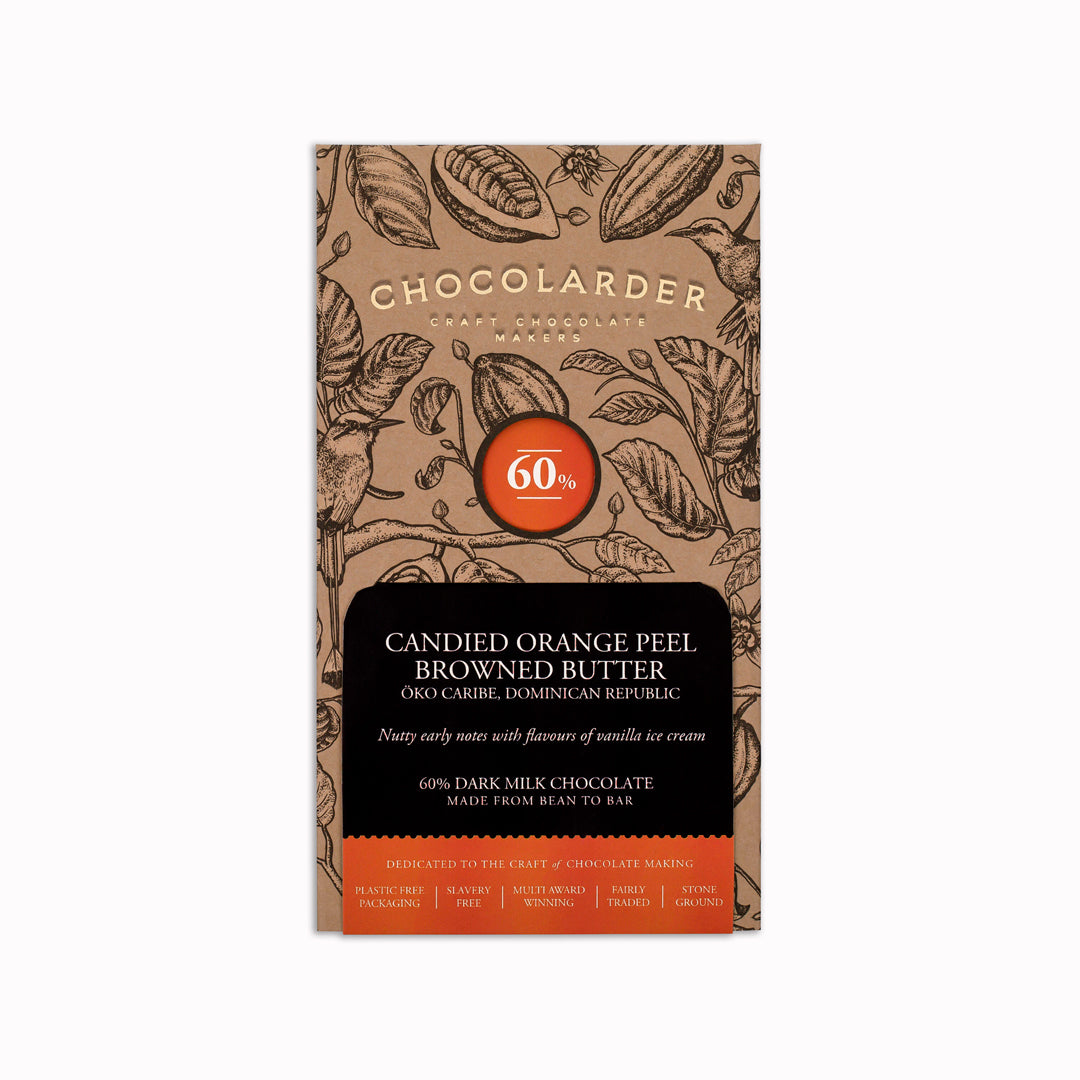

Chocolarder are UK bean-to-bar chocolate makers based in Falmouth, Cornwall. Started by pastry chef Mike Longman in 2012, the bars have won multiple awards and the company has been actively involved in reforestation projects around the world.

It was Mike’s commitment to ethical and sustainable practices that led to Chocolarder standing for more than just great flavour. Committing to zero-carbon alternatives wherever possible

They produce fine quality, stone ground chocolate using organically grown beans sourced from single estate, family run plantations across the world.

Direct Source

Chocolarder source direct from the farmers themselves. By establishing a direct channel from the farm to their kitchen, they can be picky about the quality of the beans and be sure that the money they pay for is going to those who do the real work. Having found reputable growers producing high quality beans, they commit to purchasing their harvest always for above the market prices.

Chocolarder produce chocolate based on the principles that have always been at the heart of great food – unadulterated sensory enjoyment without compromise. No shortcuts, preservatives, bulking agents, substitutions, or artificial shenanigans. Just the real deal, right from the bean to the bar.

Rethinking Chocolate

The Bean-to-Bar Revolution

The term Bean-to-Bar chocolate was coined as a way for Craft chocolate makers, some of whom would be producing just a few hundred bars at a time, to distinguish their product from mass produced chocolate and that made by chocolatiers, who melt chocolate that they buy in to make chocolate confectionery.

Bean-to-Bar is a revolution in the chocolate industry and USTUDIO are glad to be on board, stocking a great range of chocolate from artisan, small-batch producers from around the world, with a particular focus on those based in the UK.

Out With the Old

There are a lot of problems with the traditional chocolate industry. The environmental impact of manufacture, guaranteeing fair pay and fair working conditions for farmers, and variation in the quality of cacao are all problematic within the mainstream industry.

In With the New

In sharp contrast, Bean-to-Bar chocolate makers are involved at every stage of production. All the way from the cacao bean to the finished bar. This ensures the sustainability, ethics, and quality of the chocolate produced. And it also ensures that it tastes heavenly!

How it Works

What is Bean-to-Bar?

The Bean-to-Bar process is at the heart of all our suppliers’ chocolate making. The chocolate is handcrafted, from a raw cacao bean all the way through to a finished bar. The incredible flavour of the cacao is honoured, unlike in the mass-manufacturing process which focuses on keeping costs low and products consistent. Industrial chocolate is cheap because it is full of unnecessary and harmful fats, e-numbers and additives, and often has less than 20% cacao content.Craft chocolate makers buy cacao in small amounts, working directly with the farmers, and then take on the whole process of creating their chocolate, including cleaning, roasting, cracking, winnowing, and grinding the cacao beans, conching and tempering the chocolate. It is a lengthy process, but the results speak for themselves

First Steps

The first job when the beans arrive from the farmer is to hand sort them, preparing them for the roast. This process involves removing spoiled beans and any foreign materials. If hand sorting through endless kilos of cocoa beans sounds time consuming, well that’s because it is!

Roasting the Beans

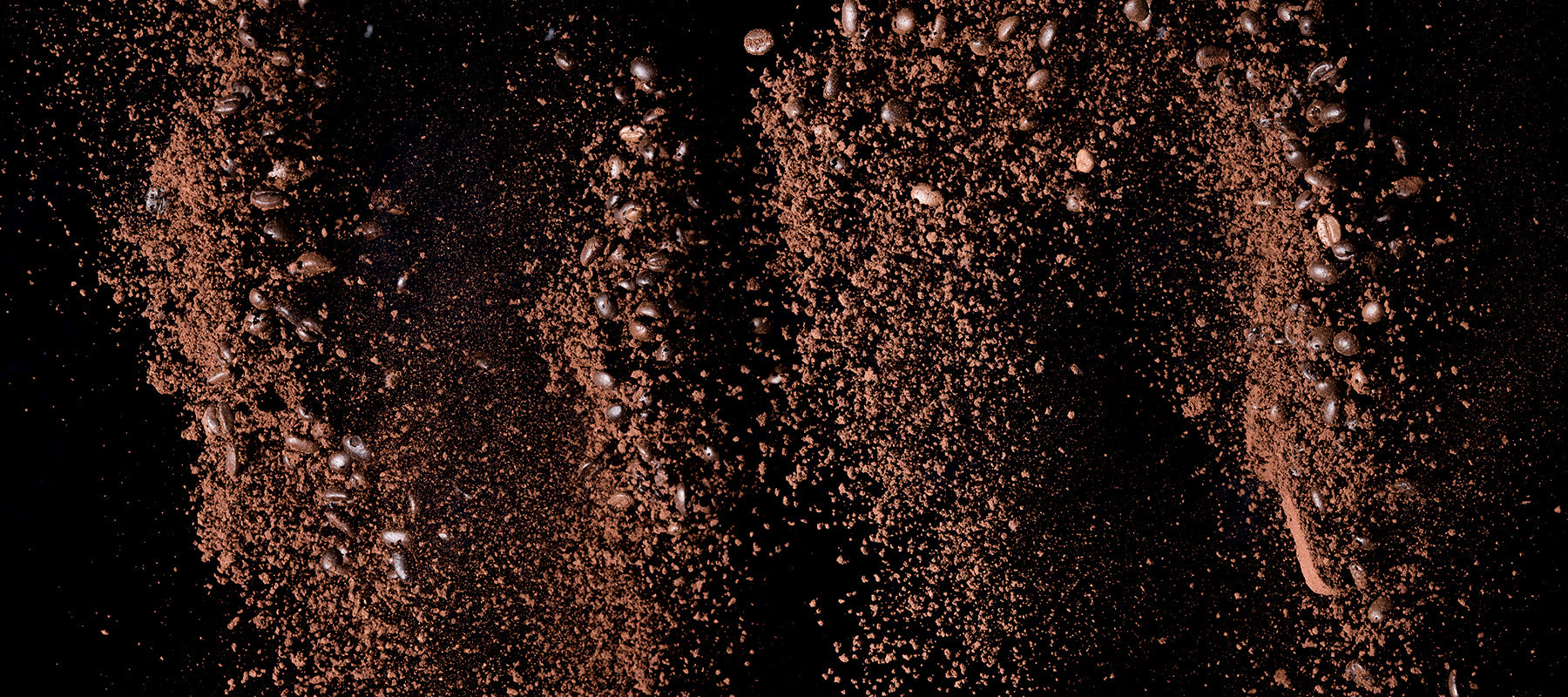

The next stage is roasting, to bring out the natural flavour and personality of the cocoa bean- every variety is distinctly different and will be roasted accordingly. Roasting drives off volatile acids from the beans and converts amino acids and sugars into tastier fully formed flavour compounds through the browning process.

A Lengthy Process

Care and Attention

Next step is to crack open the beans and discard the unwanted husks. Then the cocoa nibs are thrown into a grinder. These machines break down the nibs and sugar over a 72 hour period into liquid form. By the end of the grind particle size reduces to something between 15-20 microns, something that feels smooth on the tongue.

The chocolate is then moved onto the conching phase for some final flavour development. This involves agitating the chocolate to improve mouthfeel, drive off any left-over volatile acids and coax out the deeper, more nuanced flavour notes.

Finishing Off

The final step before wrapping is tempering, which gives chocolate structure and a nice shine. It involves heating and cooling down the chocolate and allowing the cocoa butter to crystallise. It’s this crystallisation which is crucial to giving chocolate its glossy finish

Vegan-Friendly Options

Naturally, all of our Craft Chocolate makers' dark chocolate is vegan, and we have many different sorts to choose from! In addition, some of our suppliers also make delicious oat milk and cashew nut milk chocolate, so vegans get a milk chocolate option!

Chocolarder Chocolate | FAQs

Chocolarder make bean to bar craft chocolate in Falmouth, Cornwall, in the UK. They are one of a handful of UK craft chocolate makers.

Founded in 2012, Chocolarder started as the passion project of Mike Longman, a former pastry chef.

Bean-to-Bar is a phrase coined to describe craft chocolate makers who oversee the whole process of making chocolate-from selecting the beans all the way to wrapping the finished, high-quality chocolate bar.

Ethically, bean-to-bar chocolate is a positive choice as the farmers are paid fairly and the producers focus on sustainability. Taste-wise, so much care goes into making the bar and getting the best from the cacao that it tastes amazing!

Yes! All of our suppliers' dark chocolate is vegan, and we also stock some oat milk chocolate options.

This process is similar for most chocolate makers, starting with the fermentation of the cacao beans then drying, winnowing and finally conching. then the chocolate has to be moulded and wrapped. This whole process takes around 7-10 days. Letting the chocolate rest for a few weeks after making enhances its flavour too.

'Cocoa' is essentially an English corruption of the Spanish 'cacao' which came in turn from the Mayan 'kakaw'. Nowadays 'cocoa' can also refer to a ready-mixed powder for a hot chocolate drink in the USA, but in general the terms 'cacao' and 'cocoa' are interchangeable.

Chocolate does contain caffeine, but much less than a cup of coffee! Dark chocolate has more caffeine than milk (but not much) and white chocolate doesn't contain any.

how to eat craft chocolate

The 7 Steps to Heavenly Taste

When a craft chocolate maker has put in the time and effort to make bean-to-bar chocolate, you really want to get the most out of eating it. A mindful approach is the way forward, engaging all of your senses and taking your time over each stage.